High frequency welding H-shaped steel

Category:

High Frequency Welding H-shaped Steel

Message

Product Description

High-frequency current is used to locally heat the metal surface, and it is welded under the action of external force. It does not use any welding wire or flux, and can be continuously produced in large quantities. The two pieces of shunt end pieces (T profile, H59-1 brass) are combined with 5 resistor sheets (thickness 1.5, width 20, length 45, manganese copper plate); use high-frequency heating; weld with copper-phosphorus special solder; requirements: brazing process ≤1min, focusing on solving: positioning and welding problems (in the past, brazing The welding process adopts gas welding method). Main technical and economic indicators: there is no oxidation on the surface of the product after welding, and the welding quality is higher than that of gas welding; the end piece and the resistor piece are reliably welded without melting or deformation; the resistance performance of the shunt is guaranteed; the production efficiency is doubled.

The technical characteristics of high-frequency welding H-shaped steel are: (1) fast welding speed, which can reach 18-45m/min; (2) small thermal impact, easy to control the deformation of H-shaped steel; (3) H-shaped steel with different material combinations can be welded; (4) Micro-tension production can be achieved and welding stress can be reduced. Technical level: (1) High cross-sectional dimension accuracy; (2) Excellent cross-sectional performance; (3) Cross-sectional dimensions can be customized according to user requirements.

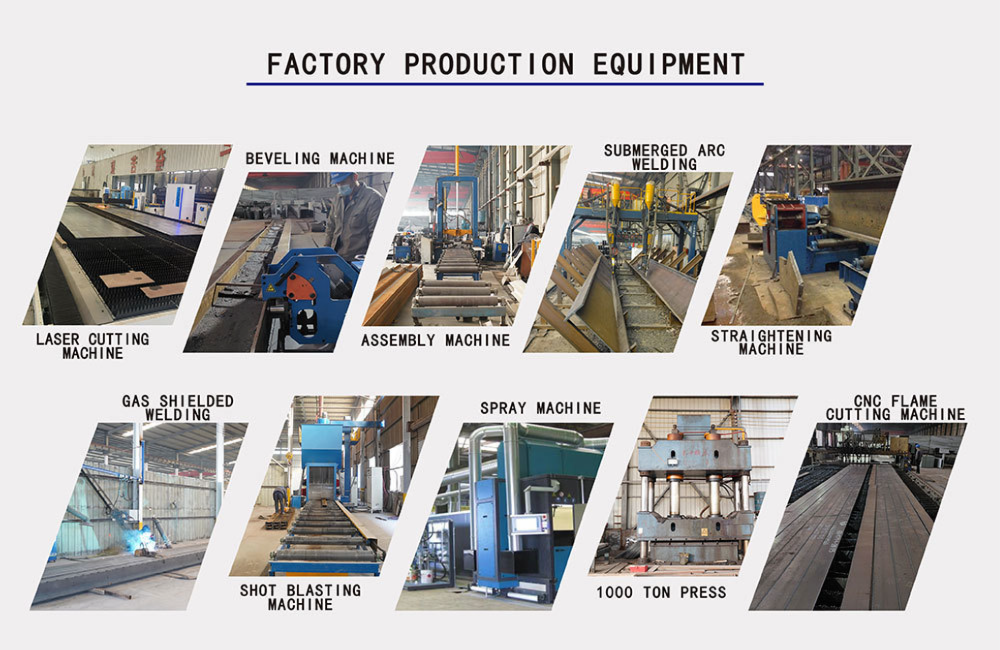

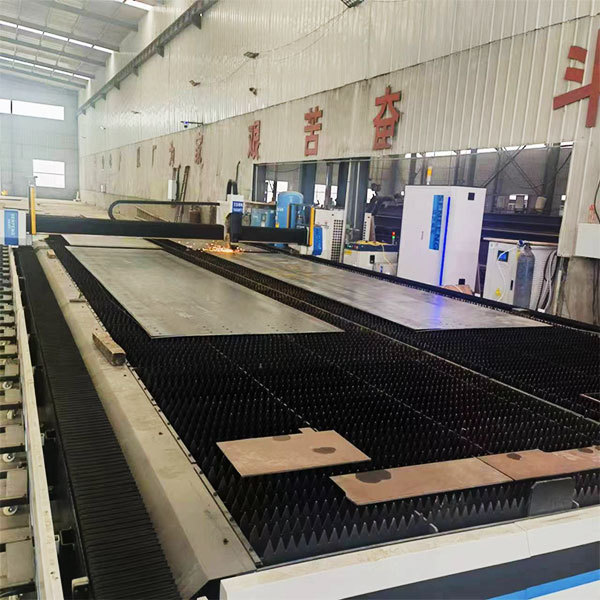

Factory

FACTORY 8

FACTORY 7

FACTORY 1

FACTORY 2

FACTORY 3

FACTORY 4

FACTORY 5

FACTORY 6

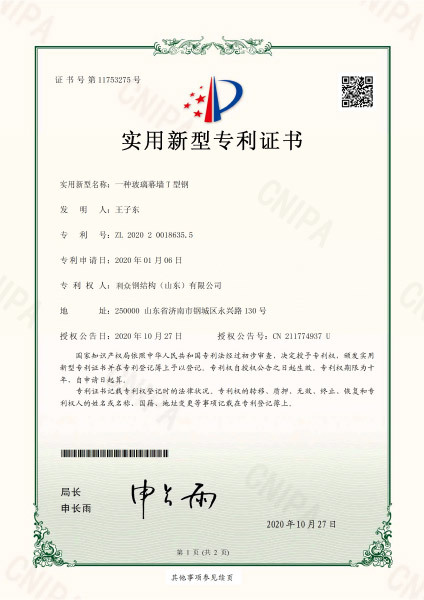

Honor

RELATED PRODUCTS

MESSAGE